Redundant function and Application of Power Supply

By: Willard Wu/ Technical Dept.

willard@meanwell.com

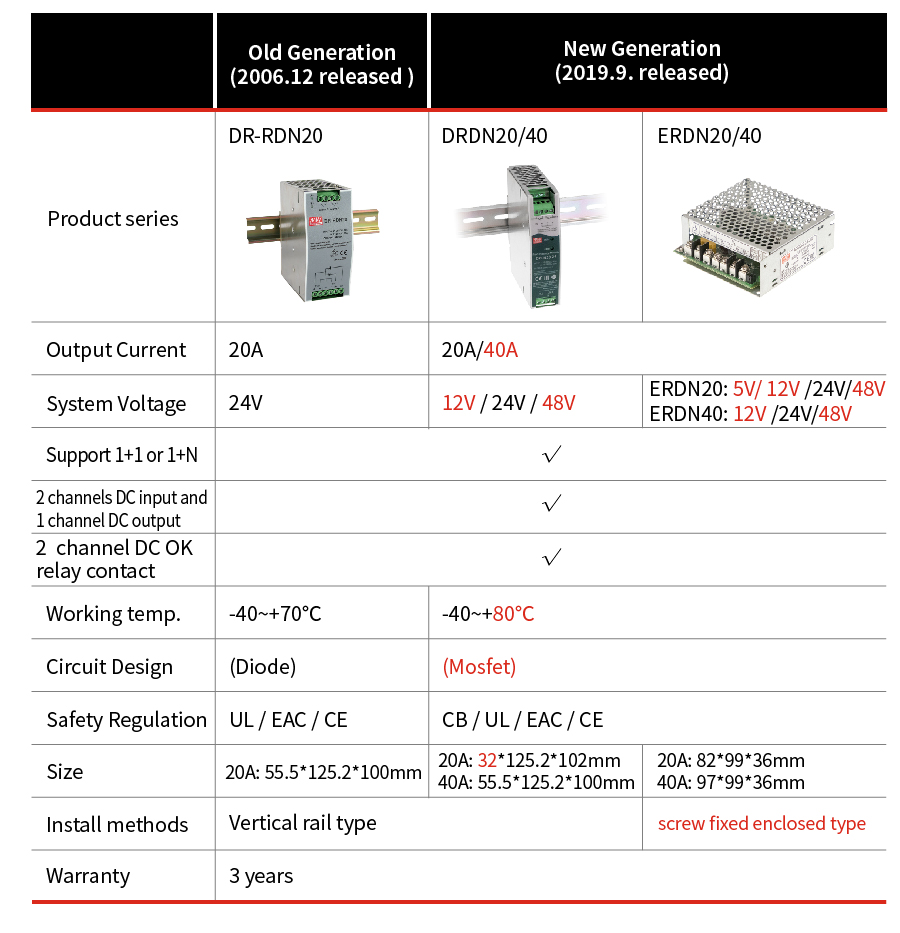

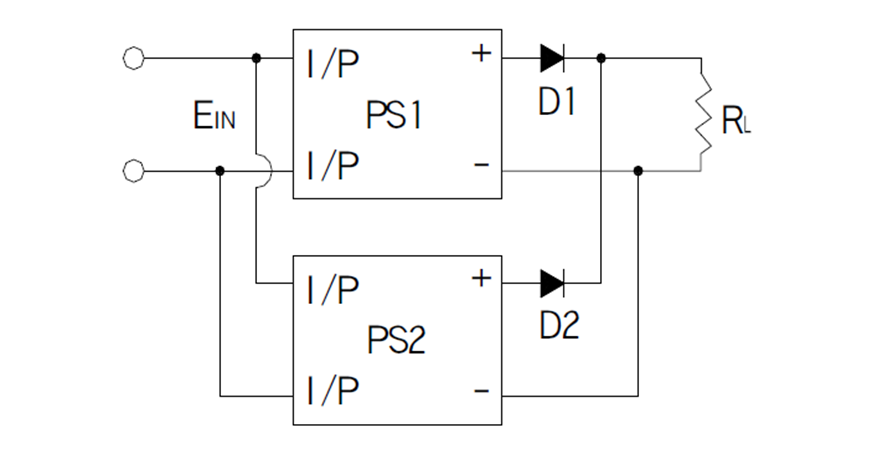

With the rapid development of technology, the requirements for the stability of power supplies of precision instrument applications, such as industrial computers, server and telecommunication equipment become more and more restricted. Generally, end system manufacturers use two power supplies and connect to the load through diodes in series as shown in Figure 1, to achieve redundant function. The concept of this design is, when one of PSUs malfunctioned, the other PSU will take over the place, ensuring the stability of the power source of the entire system. In addition, it is not recommended to select power supplies with parallel function, but without hot-swap function to be utilized for redundant function because even with parallel function, there’s still a possibility to cause a short circuit due to the damage of the output of power supplies, leading entire system malfunction.

Figure 1. External diode connect in series at output

- As shown in figure 2., VRRM shall be greater than the output voltage to prevent reversed voltage.

- As shown in figure 2., IO is suggested to be twice as high as that of the PSU output , to ensure sustainability.

- As shown in figure 2. , The lower the forward voltage Vf of diode, the better. Therefore,Schottky diode is recommended. With the low vf characteristic of Schottky diode, operating temperature is much lower and heat sink size for diode can be minimized.

Figure 2. Specification of Schottky diode ESAD83-006R

The redundant function is usually designed and verified by system manufacturers. However, not all manufacturers are capable of doing so. Thus, system manufacturers can choose products with redundant functions, such as UHP series, power supplies with redundancy option, or redundancy modules. In the past, MEAN WELL introduced the DR-RDN20 series, a DIN rail shape power supply parallel redundancy module with diodes, heat sink and other functions being integrated, which is convenient for customers to assemble for redundant applications.

Due to the increasing demand for redundant products, the volume and efficiency of the old redundant modules no longer fulfill the needs. MEAN WELL developed the new generation redundant products, DRDN20/40 series, and also introduced the enclosed type, ERDN20/40 series. The differences between different generations are shown in figure 3.

DRDN20 / 40 and ERDN20 / 40 series are a series of 20A / 40A parallel redundant modules. They can be used with power supplies for redundancy to improve the overall system operation stability and reliability. The main features include support system 1+ 1 and 1 + N redundancy, suitable for 5V (ERDN20 only) / 12V / 24V / 48V system voltage, built-in two DC OK relay contacts can be used for power status detection. Instead of using diodes, MOSFET is implemented to reduce heat and voltage difference between input and output voltage, and last, with ultra-wide operating temperature of -40 ~ + 80 ℃. With all these advantages, that makes it suitable for applications that require an uninterrupted operation.

For detailed functions, please refer to the product specifications.

For actual operation, please refer to the following videos.