Digital communication and applications of programmable power supply

By: Gabriel Li /Technical Service Center

gabriel@meanwell.com

From rotary phones to smartphones, from traditional fuel vehicles to digitally controlled electric vehicles, switching power supplies also have the exact differences between generations. Generally speaking, power supply management, including function control and status monitoring, is realized differently by three common means. First, the output voltage trimming is a function that allows the user to change the output voltage of a power supply via an external DC source. Second, Status Display the most common way is by using LED indicators. Third, Power Good signal tells the user or controller that the power supply's output voltage is ready. The above examples might meet the demands of the majority of applications, but not for every case. With the development of modern technology and automation, the traditional way no longer satisfies the users, as they need to process more information about the products simultaneously.

MEAN WELL provides either CANBus or PMBus protocols to meet customer’s newly demands.

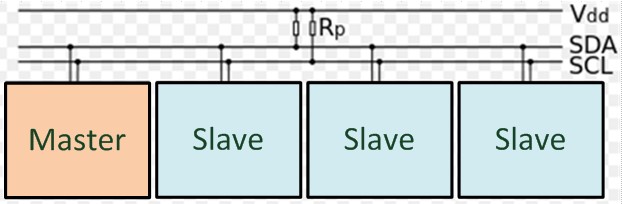

The Power Management Bus (PMBus) uses two bidirectional lines, Serial Data Line (SDA) and Serial Clock Line (SCL), meaning it only needs three signal wires (including a GND wire) connected between devices for communication via commands. For instance, a controller unit (master) can talk to each power supply (slave) over the bus to achieve system control and monitoring with multi-power supplies. This method significantly reduces the volume of control and signal wirings relatively mitigate, resulting in a lower incidence of circuitry failure and increasing the system controllability and simplifying installation. PMBus has been implemented in various fields, such as industrial automation equipment and telecommunication equipment. Figure 1. The information of the PMBus that MEAN WELL using are as follow

Advantage: Open protocol makes developers easier to design in PMBus in their system.

Disadvantage: Lower immunity to electrical interference, suitable for short-distance communication.

Figure 1 MeanWell PMBus

Protocol interface: SMBus 1.1;Version: PMBus 1.1;Bus speeds: 100KHz

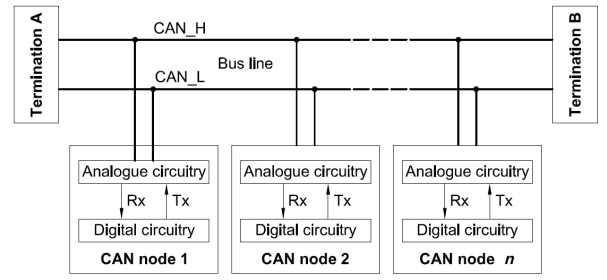

Controller area network (CANBus), which utilizes the differential signalling method(CANH and CANL), was initially developed for the automotive industry to replace the complex wiring. With the features of high immunity to electrical interference and the ability to self-diagnose and repair data errors, CANBus becomes more prevalent in various industries, including manufacturing and automation systems. Figure 2. The information of the CANBus that MEAN WELL using are as follow.

Advantage: High immunity to electrical interference.

Disadvantage: Part of the protocol is defined by MEAN WELL; modification might need requiring when implementing to end system.

Figure 2 MEAN WELL CANBus

Physical layer: 11898; Data link layer: CAN2.0B;

Application layer: Defined by MEAN WELL; Baud rates: 250Kbps

Two following actual examples are shown as follow.

Application: Automatic Guided Vehicle(AGV)

Model : RPB-1600-48 (built-in PMBus)

Communication interface: PMBus

This application uses two RPB-1600-48 installed in parallel in the charging station of the Automatic Guided Vehicle in the logistics warehouse. When the truck returns to the charging station, the system will detect the port's connection status and using PMBus to turn on the charger to charge the battery. As shown in Figure 3 the system will also select the appropriate charging current to charge the six battery packs of the truck through PMBus and send back charging information and power status through communication.

Figure 3 Automatic Guided Vehicle

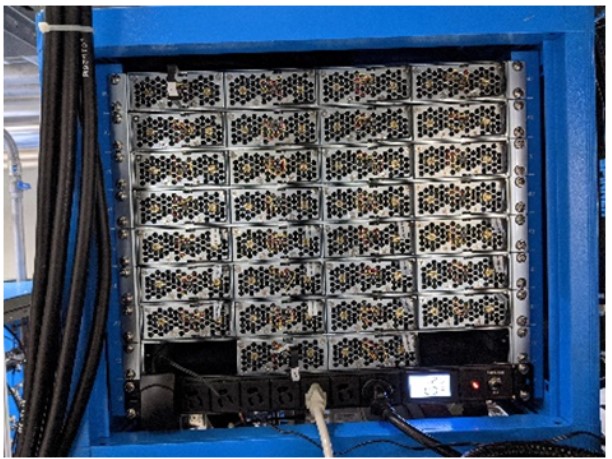

Application: National Synchrotron Radiation Research Center of Taiwan

Model: DRP-3200-48CAN (Optional CANBus)

Communication interface: CANBus

This case of the 96kW project applies multiple sets of the high-power power supply system. The output from the power system is for driving solid-state Radio Frequency Power Amplifier clusters shown in Figure 4, which generates high-frequency energy for boosting electrons to travel at nearly light speed. To match RF power required by the storage ring and best power efficiency, the output voltage of the power system must be adjustable between 42Vdc to 54Vdc modulation range for each operating point with a specific RF power level to achieve the best result.

The DRP-3200-48CAN is equipped with CANBus digital communication protocol and can operate up to 30pcs in parallel simultaneously. In addition, it can achieve the requirement of precise voltage trimming through digital communication. Furthermore, the bus voltage of each set of power systems are not connected in parallel; they need to be adjusted synchronously during experiments. For synchronization and remote control, external controllers and communication protocol are must require. Another challenge is that output power accuracy is limited to +/- 1% after trimming. To accomplish it, a power supply with a fully digital design and communication protocol makes it possible to control and monitoring the system remotely through Ethernet!

Figure 4. The configuration of the 96kW system

The MEAN WELL programmable power supply with communication function not only makes complex control and monitoring simple. The model is suitable for various applications, including RSP-1600/2000 and DPU-3200 for general applications, RCP-1600/2000 and DRP-3200 for cabinet applications, and UHP-1500/2500, PHP- 3500/3500-HV for fan-less or water-cooled applications. They all are suitable for applications requiring intelligent control and monitoring.

If you have any questions about our smart control application, click the link to the FAQ website or scan the QR code below. For more detailed instructions, please directly contact the MEAN WELL sales or technical service centre personnel. For more technical videos and articles, please link to our MEAN WELL Expo Technical Service Hall for more information.

FAQ of intelligent control

https://www.meanwell.com/qa.aspx?c=14

MEAN WELL Expo Technical Service Hall

https://expo.meanwell.com/exhibition_12.html

Reference

- 維基百科:I2C

- 國際標準ISO 11898-2